The importance of knowledge...

So let's get into one of the things that helps set us apart. When you're going through the process of paint correction, scratch removal or any other process where you're going to physically abrade at the clear coat of a vehicle you need to understand how aggressive you can be. More importantly, you want to know how aggressive you can't be when tackling this kind of work.

We believe that every car has a story to tell, and before we write our chapter in it's book we need to know where we are. Before taking a polisher to any vehicle, we want to know more about the paint, it's defects and it's history. In other words, we want the vehicle to tell us what it will or won't tolerate. Those scratches everyone wants to see gone? Well, knowing more about them will help us decide if we can remove the defect by taking material away from the car, or if we need to add material back to do it to fill it in.

To help us make an informed decision, we use a DeFelsko Paint Thickness Gauge. DeFelsko makes some of the best products in their field of measurement. The gauge we use lets us see how thick the coating on a vehicle is. By taking multiple measurements of thickness, we can determine pretty accurately how thick the clear coat is, if the vehicle has been polished too aggressively in the past or if the vehicle has even been repainted.

All of these words would be nothing without some photos to tell the story. We always begin by taking a few measurements of each panel. We are looking for big changes in the thickness that could indicate a previous repair or polishing. The gauges only measure the total thickness of the coating. In other words, the thickness from the probe to the bare metal. In order to determine approximately how much of that is clear coat, we take measurements inside the door jambs or a similar area where the factory applied clear coats are not as thick. We then subtract that average number from the readings on the external paint.

We don't ever want to remove the majority of the clear coat. The top portion of your clear coat is what really provides UltraViolet protection from the sun. We also want to leave some thickness as a barrier between damage and the bare paint of your vehicle.

Let's take a vehicle that we worked on recently that has had some paint repair done on it previously. The vehicle was an Infiniti G35.

Here you can see when we were taking readings, that we came up with 100 microns. This is a pretty standard number for a total thickness.

As we measured each panel, we came across a few that had very high readings consistently (to rule out error in the test). A reading such as this is usually indicative that there's been paint repair performed since body shops typically tend to apply paint/clear coat much heavier.

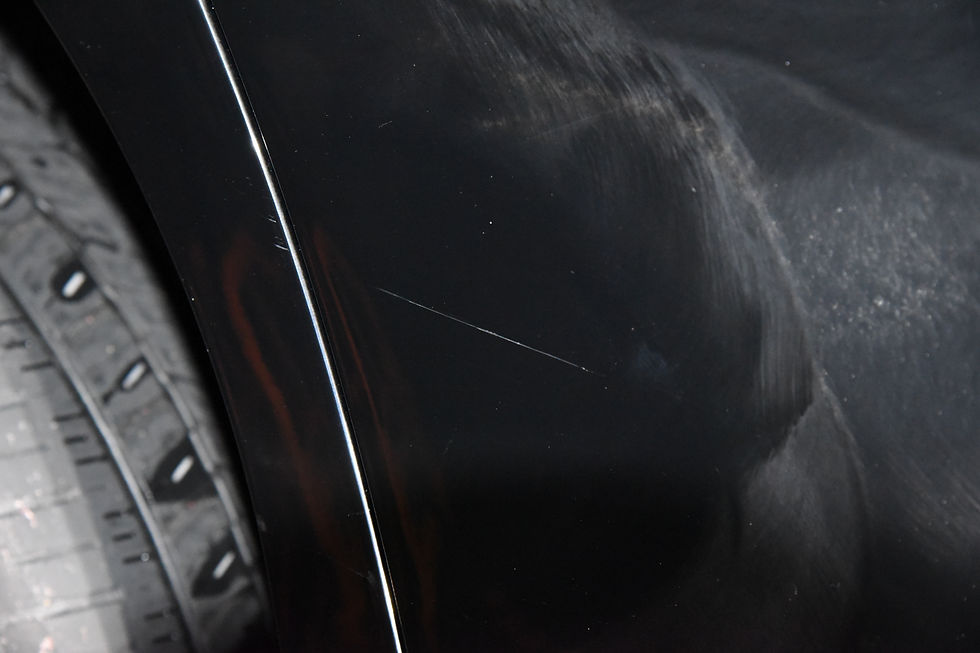

After some more evaluation, we came across a decent scratch in the surface of the paint. So before we decided how to best correct the defect, we needed to measure.

Fortunately, there is plenty of material to work with in order to go after the defect. This let us know we were safe to be pretty aggressive in going after the scratch. We worked it down using CarPro Clear Cut Compound with an aggressive pad. When we were done with this step, we were left with the defect removed and ready for final polishing. We did take a fair bit of clear coat off of the vehicle though to remove the scratch. Here's the final reading and removal (but not the final product of the vehicle).

The right tools and knowledge make a difference between "yes, we can fix that" and "oops, we made a bigger problem. When you're choosing who to have perform service on your vehicle, have a conversation with them about what they're going to do and how they're going to do it. The true professionals won't mind and will actually appreciate sharing a bit about their trade with you.